Oct. 09, 2025

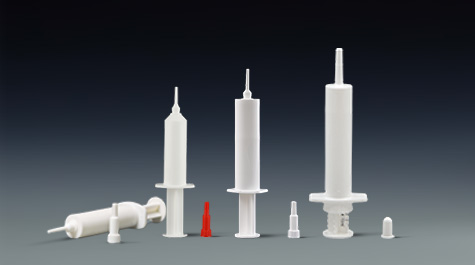

In the pharmaceutical industry, prefilled syringes have become a preferred packaging solution for their convenience and safety. However, the efficiency of drug production heavily depends on the assembly method chosen for these syringes. Selecting the appropriate approach not only enhances production line performance but also ensures precise drug filling and ultimate patient safety. This article explores two common assembly methods to help pharmaceutical companies make informed decisions.

The tip cap separate assembly method is ideal for drugs filled through the needle end. In this approach, the plunger and barrel are pre-assembled, while the tip cap is packaged separately. During the filling process, the drug is directly injected into the barrel through the needle site.

Advantages:

Enhanced Efficiency: Pre-assembled plungers and barrels streamline the production line, reducing time delays and operational errors.

Simplified Process: This method allows for quick and secure drug transfer into the barrel, making it particularly suitable for liquid formulations requiring needle-based administration.

Broad Applicability: It is widely used in high-speed production environments where simplicity and speed are critical.

The plunger separate assembly method is designed for drugs filled through the plunger end. Here, the barrel and tip cap are pre-assembled, while the plunger is packaged separately. The drug is injected into the barrel via the plunger end, ensuring accurate dosing.

Advantages:

Precision Dosing: This method offers superior control over injection volume and speed, minimizing the risk of over- or under-filling.

Reduced Contamination: By limiting exposure during the filling process, it helps maintain drug sterility.

Flexibility: It is especially beneficial for high-value or viscosity-sensitive drugs where dosing accuracy is paramount.

While the two assembly methods differ structurally, each offers unique benefits tailored to specific drug formulations and production requirements. Pharmaceutical companies should consider the following when making a choice:

Drug Characteristics: For needle-end injections, the tip cap separate assembly method simplifies operations. For drugs requiring precise dosing, the plunger separate assembly method is more suitable.

Production Workflow: Aligning the assembly method with existing production lines can reduce costs and minimize workflow disruptions.

Supplier Collaboration: Engaging with experienced prefilled syringe suppliers ensures access to tailored solutions that meet regulatory and operational standards.

The assembly method of prefilled syringes plays a pivotal role in pharmaceutical production. By understanding the strengths of each approach—whether tip cap separate or plunger separate assembly—companies can optimize efficiency, ensure drug safety, and strengthen their competitive edge. Partnering with knowledgeable suppliers further guarantees that production processes are both innovative and reliable.

veterinary syringe

冀ICP备11016487号-1

冀ICP备11016487号-1